Teamcenter PLM

Teamcenter stands as a pioneering Product Lifecycle Management (PLM) solution, digitally uniting individuals and workflows spanning various functional divisions. With Teamcenter, you can effectively bring forth intricate products while optimizing efficiency and simplifying procedures.

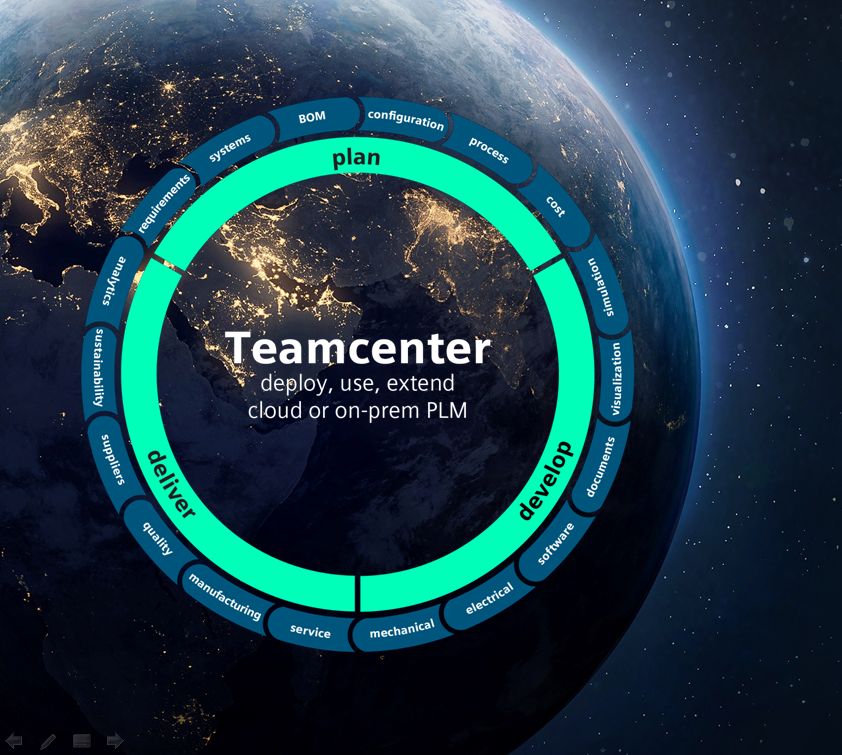

Plan, Develop and Deliver innovative products with Teamcenter software

- Set the strategic direction and product definition to guide downstream decisions.

- Design and document the multi-discipline product to leverage the digital twin.

- Weave the digital thread to connect product development with manufacturing, service and suppliers.

Leverage the digital twin

Use digital twins to connect and optimize processes for designs, systems, software, simulation and visualization. Resolve problems before they become real.

Collaborate and innovate

Connect people across your business. Automate and streamline product lifecycle processes. Provide visibility for everyone to make innovative product decisions.

Rely on the leader: Worlds No 1 PLM

Start-ups to large enterprises – across industries – trust Teamcenter. Invest in the future with modern PLM of unmatched breadth, depth and usability.

Explore Teamcenter PLM Solutions

1. Plan for Performance and Profitability

Integrated requirements engineering

Requirements describe what your customers will buy. Integrating them with the product lifecycle allows them to drive all aspects of the product lifecycle toward consistent compliance, creating compliant-by-design products.

MBSE: Model-based systems engineering

Product development without integrated architecture is like building without blueprints. System integration can consume as much as half of your program’s resources. Start using model-based systems engineering (MBSE) early on for continuous integration.

Bill of materials (BOM) management

Meet the challenges of your innovative and varied product offerings. Use unified, design-aligned multi-domain bill of materials (BOM) management. Author and release configured products while effectively managing change and downstream processes.

Product Configuration Solutions

Meet rising demands for consumer choice and product personalization without driving up costs. Handle more options with less effort – Use a single definition of variability from product planning to manufacturing and service.

PLM process management

Take control of planning, schedules, resources and processes – including change cycle time – to realize better project, product and program execution.

Product cost management

Determine and evaluate product and tool costs, product carbon footprint, and profitability at the start of the product lifecycle.

2. Develop across Departments and Domains

Mechanical Design Management

Improve engineering productivity by up to 25%. Find, share and re-use mechanical CAD (MCAD) data in a fully integrated, multi-domain PLM environment.

Electrical CAD and electronic systems management

Fully manage the entire electronic design cycle from schematic capture to manufacturing – in alignment with mechanical and simulation engineers. Improve engineering productivity for ECAD. Find, share and re-use electrical and electronic CAD data in a fully integrated, multi-domain PLM environment.

Software design management

Synchronize, orchestrate and align your software and hardware product development lifecycles to deliver high-quality cyber-physical products.

Product document management and technical publications

Create, manage and deliver product documents and technical publications for all stakeholders – from engineering to marketing, manufacturing, service and support.

Product visualization and digital mockup software

Build better products, faster. Streamline design and review cycles, improve communication and increase innovation – across the product lifecycle.

Simulation process and data management

Find, share and re-use simulation and test data and processes in a fully integrated, multi-discipline PLM environment to improve engineering productivity.

3. Deliver Product Visibility and Insight

Product lifecycle management analytics

Find data, gain insights and make smart product decisions faster. Monitor performance throughout the product lifecycle.

Sustainable product development

Design, procure and manufacture for sustainability with a comprehensive green digital twin.

Supplier management software

Coordinate processes, manage information and drive early supplier involvement across all stages of the product lifecycle.

Quality and compliance management

Leverage integrated quality and compliance management in PLM to exceed customer expectations and deliver premium quality products.

Manufacturing process planning and data management

Get into production faster with Teamcenter manufacturing process planning and data management. Collaborate instantly and securely to optimize part production and assembly operations

Service lifecycle management

Integrate your service bill of materials (BOM) with engineering, improve quality with service asset management and planning, and manage physical structures to improve first-time-fix rates.

We Coimbatore Cad Solutions Pvt Ltd would love to meet you and let you the perfect Teamcenter PLM solution

Teamcenter

Host, Manage and Support your PLM software on your premises

Product Lifecycle Management your way

Get Teamcenter PLM delivered the way you want it – on premises or on the cloud

Teamcenter X

Get Started quickly using your PLM software as a service.

FAQ

Most frequent questions and answers

Product Lifecycle Management – PLM is a comprehensive information management system, seamlessly weaving together data, processes, and business systems across the entire product lifecycle. Harnessing PLM software enables swift reductions in time to market, enhancements in quality and sustainability, bolstered efficiency, and cost reductions, all achieved through the power of well-informed decision-making.

Teamcenter software is a modern, adaptable product lifecycle management (PLM) system that connects people and processes, across functional silos, with a digital thread for innovation.

Teamcenter X software is a cloud software-as-a-service (SaaS) delivery option for instant-on Teamcenter adoption. Created with innovators in mind, Teamcenter X builds on Siemens’ experience in PLM to help companies get up and running quickly so they can grow. Teamcenter X is easy to deliver and easy to use for people across your business so they can participate in product lifecycle processes.

Teamcenter X offers swift access to preconfigured PLM functionalities, featuring a user-friendly interface rooted in industry-leading practices. It empowers you to efficiently handle and disseminate information, expedite product-related workflows, and effectively steward your invaluable engineering knowledge. Whether working remotely or in-office, Teamcenter X ensures secure access to product lifecycle data, facilitating seamless collaboration across diverse environments. With Teamcenter X, the advantages of PLM become instantly attainable.

A digital twin is a virtual portrayal of an object or system meticulously crafted to faithfully mirror its physical counterpart.The digital twin is the underlying premise for Product Lifecycle Management and exists throughout the entire lifecycle of the physical entity it represents.

It is composed of the following three elements:

- A physical entity in real space.

- The digital twin in software form.

- Data that links the first two elements together.

A digital twin functions as a proxy for the current state of the thing it represents. It also is unique to the thing represented, not simply generic to the category.

A digital thread creates a closed loop between digital and physical worlds to optimize products, people, processes, and places. A digital thread is the flow of information about a product’s performance and use from design to production, sale, use and disposal or recycling. This provides insights into how customers use products, how those products perform, how they could be improved and what new features customers might want

Why Coimbatore Cad Solutions Pvt Ltd?

Coimbatore Cad Solutions Pvt Ltd is a premier reseller for SIEMENS Digital Industries Software, specializing in Electromechanical 3D Design, CAM, Simulation, and Product Lifecycle Management software. Renowned for our excellence in delivering SIEMENS Design and manufacturing automation solutions across India, we’ve expanded our operational footprint and clientele, catering to diverse sectors encompassing small, medium, and large enterprises. Coimbatore Cad Solutions Pvt Ltd is a certified value added reseller for Teamcenter in India. With Coimbatore Cad Solutions Pvt Ltd, you can always expect to make more value from your software investments